The Institute of Advanced Architecture of Catalonia (IAAC) presented TOVA in February 2023 its first building printed in 3D using earth. Construction was completed in a matter of weeks using 100% local materials and local labor, generating zero waste with almost zero carbon footprint. Utopia?

While in France the architectural schools strong in their teachers-researchers are adrift and while to save the planet politicians women and men insult each other with dogmas and well understood interests without ever going beyond the effects of he announcement, the Institute of Advanced Architecture. of Catalonia, away from those ideological disputes, seeks and finds promising political, ecological and architectural solutions. The students and their teachers are not just talking about it, because the first prototype literally came out of the ground.* Presentation.

The project results from the IAAC’s ongoing research into 3D printing architecture with the aim of developing realistic architectural solutions that use additive manufacturing to provide sustainable, affordable and community housing construction processes. Developed by the team of students and researchers in the 3D Printing Architecture (3dPA) of IAAC, this production system is globally replicable and represents a promising response to the global increase in material crises.

The construction was done at the Valldaura Labs facilities, in the Collseolla Natural Park, on the outskirts of Barcelona. The prototype, completed with locally sourced clay materials, testifies to the potential of 3D printing with sustainable materials, in response to current climate challenges. TOVA further demonstrates the importance of implementing past craft techniques – vernacular architecture – with those of the future – large-scale 3D printing technology – in the contemporary built environment.

“TOVA” is the beginning of a larger research project in collaboration with WASP, which will result in the construction of a complete 3D printed house using clay materials.

Fast, waste-free and adaptable construction

It is the first building of this type in Spain. It stands out as one of the most sustainable and environmentally friendly forms of construction that can be applied today. Construction takes place over seven weeks with WASP, the architectural 3D printer, and uses only km zero materials.

During the entire construction process, no waste is generated because the materials are sourced from a 50-meter radius. The structure is made from local soil, mixed with additives and enzymes, to ensure the structural integrity and elasticity of the materials necessary for the optimized 3D printing of the work.

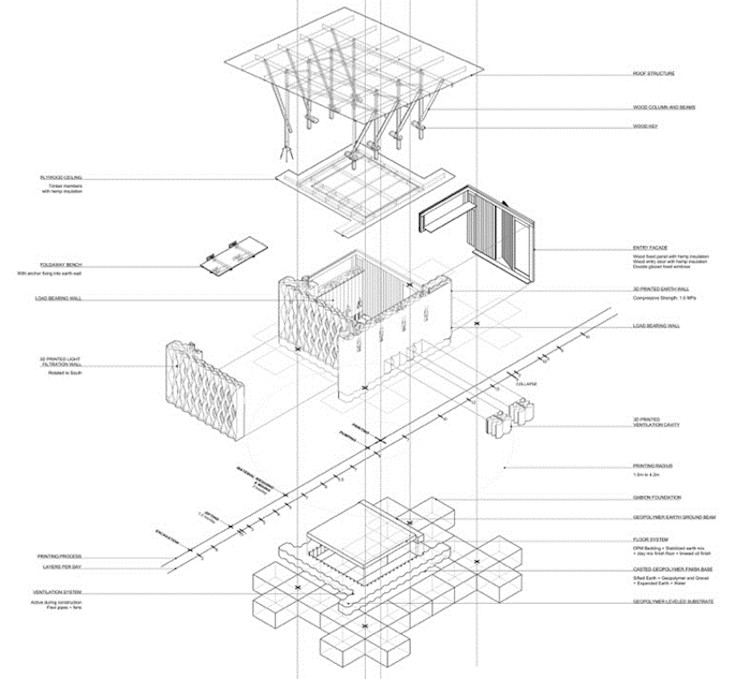

The foundation is in geopolymer, the roof in wood. To ensure the material’s longevity in weather resistance, a waterproof coating is added using extracted raw materials such as aloe and egg whites.

The design of the building is based on a precise analysis of the climatic conditions of the Mediterranean Sea. The volume is compact to protect against the cold in winter, but expandable for the other three seasons, considering semi-outdoor spaces as part of the living space. To this end, the wall section, consisting of six earth surfaces and a network of cavities containing either air or insulation, was calculated to prevent heat loss in winter, while protecting solar radiation in summer.

This is a project of almost zero emissions: the design is studied and tested through digital and physical simulations with the aim of reducing construction footprints, monitoring CO² reduction and taking into account the life cycle assessment of building components, which makes it a pioneering example. of low-carbon construction, knowing that current construction methods are responsible for around 40% of CO² emissions.

The possible applications of this building model are endless; from homes to public spaces, indoors and outdoors. In combination with other construction systems, it can accommodate complex and innovative construction designs that would significantly reduce the environmental impact that construction currently entails.

Housing to address the housing crisis of today and tomorrow

The project was designed as a prototype for sustainable housing that could be and adapted to various environments. This prototype made it possible and risk-free to apply 3D printed earth construction in a suitable environment, fusing both material knowledge and craftsmanship with avant-garde optimized design technology, effectively solving the problems of Access to housing in vulnerable areas or temporary settlements, offering. new solutions to create more sustainable and affordable spaces.

Continuous on-site printing of locally sourced materials has a great advantage in reducing the carbon footprint of buildings, saving in material transportation as well as material processing, since the earth is extracted from the construction site and used in its raw state during collection. Additionally, the printing system enables highly customizable homes for different use cases; as communities of homes and services that can be quickly created using this technology in various places and conditions.

With TOVA and other projects, IAAC responds to increasingly serious climate and migration crises, providing new solutions that contribute positively to the global housing crisis that will have to be faced in the future due to large migration or natural disasters. The use case for this rapid construction method may be a solution to increase habitat requirements in emergency response scenarios.